Augmented Reality Advancement: Romer Arm Scanner

DirectProject is an augmented reality application that uses 3-D optical projection to service in measurement comparison points and PolyWorks, by means of a scanning arm. Utilizing DirectProject involves various software components, including: MANUscript, ProjectionWorks Registration Utility, ProjectionWorks Hive Manager Service, DirectProject, and appropriate plugin application DLL(s). Incorporating these components allows you to achieve a projection from an external software.

Compatibilities

Currently, the 3-D display data supports the following data formats:

Currently, the 3-D display data supports the following data formats:

- 3DXML

- X3D

- VRML

- PLY

- OBJ

- CSV

- STL

While this projection application is growing in capabilities, you may need adaptation for a different system; however, there may be a way to accomplish it.

How it works

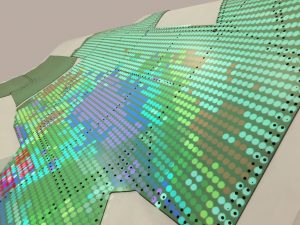

A Romer Arm Scanner is used to measure surface deviation from the Computer-Aided Design (CAD) model. If a requisite software has been properly installed on the machine, the projecting arm will need to calibrate and align with the projection system. To project the needed data, a data file will need to be created and updated according to the project specifications. From that point, monitoring the projection where white dots will show where a measurement needs to be taken. Colored dots are representative of where the white dots’ measurements have been confirmed. The different colors reflect the surface deviation from CAD values in increments of 0.005”. Another option for projecting the engineered dots, is to use the exact digital reading of the projected values of the surface deviation.

Benefits

The benefits greatly outweigh the current industry process. By allowing the display to curve, just as the body of the final project will, allows for necessary adaptation. The ability to have the curvature to the project allows the engineers to look at a map as it would be. According to Delta Sigma, “Displaying your data directly on the part where it was measured makes the data vastly more useful to your customers when some action needs to be taken based on the results of the measurements.”

Delta Sigma introduces the new capability in ProjectWorks to aid in metrology tasks. This technology shows an engineer exactly where measurements need to be taken and what actions are required to perform a specific action, which is where the true benefit of using this product lays. The technology can also show in-between values, areas within a specific percentage of tolerance, or can simply display that data as pass or fail. The data imported can represent surface deviation, flow pressure, ply voids, RCS, sub- surface cracks, and any other object that can be measured in 3-D.

[cta] To find out more information regarding this progressive technological advancement, call Delta Sigma at (770) 575-5100 or email any questions to info@deltasigmacompany.com.[/cta]