Ensuring Accurate Grip Length

Q. Our technicians are using AssemblyWorks. How can we ensure that they have the correct grip data for the particular aircraft assembly they’re working on at any given time?

Q. Our technicians are using AssemblyWorks. How can we ensure that they have the correct grip data for the particular aircraft assembly they’re working on at any given time?

A. When working with composite assemblies, technicians might come across discrepancies between the grip length that is specified in the engineering design and the actual thickness of holes in the assembly. Mismatches in grip measurements can slow the assembly process as the technician obtains different-sized fasteners.

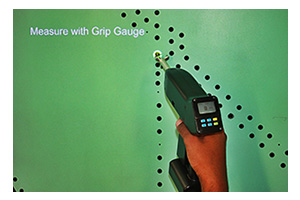

If you’re using AssemblyWorks on your line, you can make sure that your technicians have accurate grip-length data — and fasteners with the correct grip size — by using ProjectionWorks’ patented GripGage tool. This wireless device allows the user to rapidly make grip-length measurements that are correlated to a particular hole. The device can connect to an AssemblyWorks station via a 256-bit encrypted data link, and transmitted data can be used to specify a fastener kit list, based specifically on the as-built condition.

Precision hole measurement — made easy

Here’s how the device works. When a technician reaches a measurement task in the work instructions generated by AssemblyWorks, the system prompts the tech to specify which measurement device (of those detected by the wireless receiver) to use. Pairing a GripGage to a receiver is simple, and the pairing process configures them with a common key for data decryption. Only one GripGage at a time can connect to an AssemblyWorks controller, but many GripGages can be in used in a small area by connecting each to separate individual AssemblyWorks controllers.

During measurement, AssemblyWorks illuminates a hole. The technician inserts the GripGage into the illuminated hole and squeezes the trigger as the GripGage’s three-point foot settles onto the surface. (You can see GripGage in action in this video.) The measurement is captured with an accuracy of +/-0.001 inch. After one day of using GripGage, a technician can average more than 30 holes per minute, as long as the holes are near one another.

When configuring GripGage, an operator or engineer can set the allowable tolerance for each hole to a maximum and minimum value. AssemblyWorks will allow a technician to proceed after each in-tolerance measurement. However, when an out-of-tolerance measurement is taken, AssemblyWorks illuminates the hole red, highlights the line on the user screen in red, and does not advance to the next hole until the tech successfully retakes the measurement. (The tech can manually move on to the next hole, if necessary.) At any time, the tech can display recorded out-of-tolerance holes. GripGage also lets a tech take manual measurements for holes that are too deep or with a too-wide diameter.

GripGage also lets operators measure countersink depth, diameter, and flushness and associates those measurements with individual holes. The kit list shows all part numbers, including measured grips, and can be printed locally or sent to a remote MSP crib.

Correct grips, better kits

GripGage provides highly accurate measured grip values that can make your assembly operations faster, easier, and more accurate. Assembly teams can use these measurements to preassemble a presorted kit with the exact quantities of correct fasteners for the as-built condition for a particular assembly — and in the correct installation order, so the fasteners are ready for the production line when needed.

Ready to learn more about how GripGage can improve your complex assembly operations? You can find more detail about GripGage here.

[cta]For answers to your questions about Delta Sigma Company tools and solutions or ways to improve your assembly operations, call us at (770) 575-5100 or email info@deltasigmacompany.com.[/cta]