Meet the ProjectionWorks Family

Since our initial AssemblyWorks product release at the end of 2009, the ProjectionWorks family has come a long way. For the first three years, the “family” had only one member but continued adoption by industry, Delta Sigma Company (DSC) investment, and important United States Air Force contributions, greatly expanding the family over the past three years. ProjectionWorks is the global leader in augmented reality (AR) work instructions for aircraft production lines and is expanding into other industries. The following may help you better understand how the pieces fit together.

ENGINEERING

ManuScript

The ProjectionWorks family authoring package is ManuScript. This is how engineers author “manufacturing scripts” for assembly technicians to follow during mechanical or electrical assembly build processes. They also use it to create calibration models for PaintWorks and define how to interpret the data they receive via DirectProject. ManuScript is common to all ProjectionWorks applications.

PROJECTION HEAD

PV-3D

The Augmented Reality Information System (ARIS) is the hardware that contains the processor that runs ProjectionWorks software. It contains the vision system and all network connectivity to create projector constellations of any size. ARIS also provides the mechanical interface for mounting projectors to structures. It has all the hardware and software required to calibrate optics and register coordinate systems in 3D. ARIS is common to all ProjectionWorks applications.

PV-2D

In form, fit, and function, this system is identical to the 3D version — except it can only project two-dimensional objects and can only register on 2D planes. However, users can upgrade the PV-2D to a PV-3D if their needs change over time.

ProjectionWorks v4

This is the patented 3D projection engine software that runs in the ARIS and creates 3D AR projections that display 3D CAD data in full scale and full color on 3D parts or assembly surfaces. ProjectionWorks is common to all the applications listed below.

Controller

The specific controller that comes with the products below (if any) varies from product to product. A Microsoft Windows 7 or 10 computer runs the software packages, and the controller is typically a touchscreen device on an industrial stand.

Human Machine Interface (HMI)

Users can interact directly with controllers, but many prefer to use tablets, smartphones, or smartwatches as interfaces. Various options are available.

APPLICATION SOFTWARE

AssemblyWorks 3D

AssemblyWorks 3D is an AR system used to show assembly technicians how to create complex mechanical assemblies using existing 3D CAD data in full scale and full color in easy-to-follow work instruction sequences. It allows multiple operators to work on multiple tasks using the same projector constellations by working from different HMIs. AssemblyWorks 3D connects to the PV-3D.

AssemblyWorks 2D

AssemblyWorks 2D is functionally the same as the 3D version but only offers 2D data capabilities. For planar object applications — retrieving cut cards from presses or cut plies from cutting systems for kit assemblies; placing components in floor panels, wall panels, or doors; or populating electrical panels with components — AR displays can benefit 2D objects with 2D data. AssemblyWorks 2D connects to the PV-2D.

DirectProject

This system uses a customer-supplied computer and software package as the user interface. This software-only package accepts data from the host software package and provides algorithms to create and display AR data views. It allows almost any system designed for 3D data to become an AR controller and displays data on the parts — not just a computer screen. DirectProject can connect to the PV-2D or 3D.

PaintWorks

This system usually projects final finishes on full vehicles. It’s easy to visualize a paint scheme before any investment in full-scale 3D masking and actual colors. It’s also sometimes used to project masking to prepare for some type of process — primer application, for example — on machined parts. It provides users with simple visual interfaces and connects to the PV-3D.

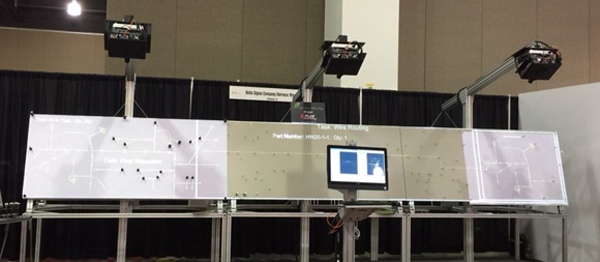

HarnessWorks

Users employ this system to create wire harnesses on standard wire boards. It can provide board setup instructions, which can be used to quickly create reconfigurable boards in just a few minutes. Users can display wire routes, bundling, lacing, tape, clamps, and termination instructions with HarnessWorks, which connects to the PV-2D.

HarnessWorks 3D

This system is functionally identical to HarnessWorks except users can work on more complex harnesses with it, and it connects to the PV-3D.

[cta]For answers to more questions about optical projection and how it can make assembly operations better and faster call the DSC experts at (770) 575-5100 or email info@deltasigmacompany.com.[/cta]