AssemblyWorks v4 Is Here!

The long-awaited AssemblyWorks v4 capabilities are here and production teams are already using them to make airplanes you might be flying in soon. We included the big features — like multi-operator, multi-coordinate, and automatic work authoring systems — as promised along with a list of other enhancements. The biggest advance from a code-based perspective is “under the hood.” Features you’re familiar with will allow future development to move at an accelerated pace with much greater stability and allow interconnectivity to all kinds of external systems.

Here are some new key features and abilities:

- Users can work in multiuser mode. They can be in the same “area” at the same time, and the system saves everyone’s changes. Larger assembly teams can divide work into smaller units, creating a faster workflow and allowing many users in the area at the same time.

- The new “guided inspection” task type tracks historical data and input issues that come up during inspections. Items that pass inspection without issue have a different color code than items with issues.

- Plugin architecture and publishing allow for customized behaviors and additions to the core platform without requiring entire software set redistribution. In addition, users can extend publishing and measurement, and the publishing plugin produces each user’s designated versioned files.

- Users can configure measurements to retrieve data from Delta Sigma Company (DSC) and Mitutoyo grip guns in addition to the standard Orgin Technologies Laser Gage, Mitutoyo digital gages, and DSC grip guns.

- Enhanced 3DXML gives users full control over which model parts should be visible in any part of a solution through complete product structure reproduction in a “folderized set within the geometry tree.”

- Data input scripting through the AssemblyWorks Rule Script Engine allows users to automatically import data from various sources. Users can provide custom rules for the data formats and file structures. Version four has set rules to accommodate many infrastructures and customized plugins that will help address outlier situations.

- Upgraded text capabilities add options for displaying the current job, task, or username when defining text in a solution and provide multiline dynamic text capabilities.

- Version four offers integrated training and alignment with combined registration, calibration, and training tools in a single application.

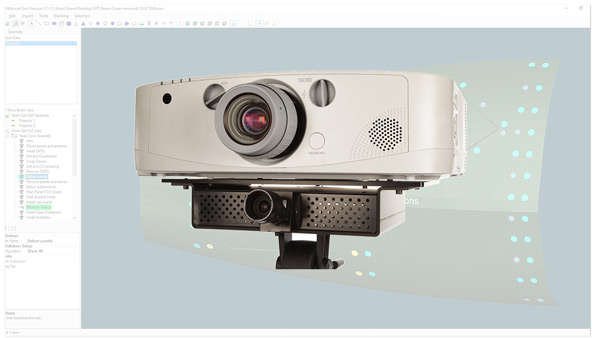

- 3-D enhancements include CAD-style mouse control integration, and the projection overview offers a 3-D view and annotated projected part geometries. Users can see the entire projection in a single view — even with large parts utilizing several projectors — as well as rotate, zoom, and pan with 3-D mouse controls.

- Redlining capabilities allow users to load the same job file version and see redlines for each new work order opened for the job. Users can document changes to the production work instructions.

Not only does AssemblyWorks v4 allow you to work more efficiently with an improved user experience and new tools but the new architecture also allows for rapid new product development. Just one month after the v4 release, DSC experts released a completely new product called DirectProject based on the new ProjectionWorks code. DirectProject already has a working interface to PolyWorks, and users can add others quickly. In some cases, attaching systems to a ProjectionWorks product will require no code changes from DSC: Just write a dynamic-link library using the ProjectionWorks application program interface and start working in the augmented reality world!