Get Your Hands On a Faster Harness

What’s the costliest part of assembling a wire harness? Likely, it’s the time technicians spend deciphering written documentation, determining the correct wire routes, and reworking the harness when there is an error.

What’s the costliest part of assembling a wire harness? Likely, it’s the time technicians spend deciphering written documentation, determining the correct wire routes, and reworking the harness when there is an error.

What if you could eliminate all those issues?

Reduce frustration, increase return on investment (ROI)

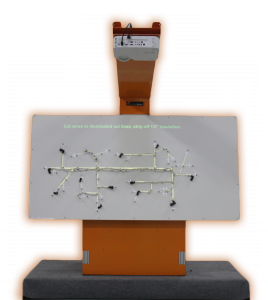

HarnessWorks — an offering from the award-winning assembly process manufacturer of ProjectionWorks — uses software and a projection system to automate wire harness assembly.

Developed with input from the U.S. Air Force and other aerospace companies, this tool creates an augmented reality view of work instructions directly on the work surface. As a result, accuracy and productivity increase as errors plummet.

How does it work?

First, you import files from harness design software or files. Choose whether to use single or multiple boards and operators. And that’s it! Instructions are projected step by step onto the work surface. Operators can navigate through steps by clicking a specific step or moving forward or back in the sequence.

The system projects CAD data, line widths, sizes, part numbers, and notes directly onto the work surface. There’s no need for operators to look away or flip through documentation.

You can use HarnessWorks to support numerous aspects of wire harness creation.

- Rules and path definition

- Routing, inspection, and test-rigging guidance

- Taping

- Clamp and wire sleeve location

- Connector closeout

- Redlines

- Board setup

- MES System and PDM integration

The tool is based on AssemblyWorks, which has a proven record of providing as much as a 40:1 ROI.

Put HarnessWorks into rotation today and enjoy immediate benefits in ROI and operator efficiency.

[cta]For answers to more questions about optical projection and how it can make assembly operations better, faster, and less expensive, call DSC at (770) 575-5100 or email info@deltasigmacompany.com.[/cta]