Ready, Player One? AssemblyWorks: The Game

To collect data for our analysis of the human performance improvement that the augmented reality products in our ProjectionWorks family provide, Delta Sigma Company needed volunteers to participate in our structured experiment. What better way to get people to participate than to turn the experiment into a game?

We did just that, creating AssemblyWorks: The Game, which we featured at the AeroDef Conference in Long Beach, California, on Feb. 9 and 10, 2016.

How we set up the game

The most important thing to understand about the experiment is that we are always evaluating the same person doing the same task in two ways. It is not a case in which, maybe, all the fast people did the augmented reality method and all the slow people did the traditional method. All 85 participants performed both methods.

Here are the key things to know about the experiment:

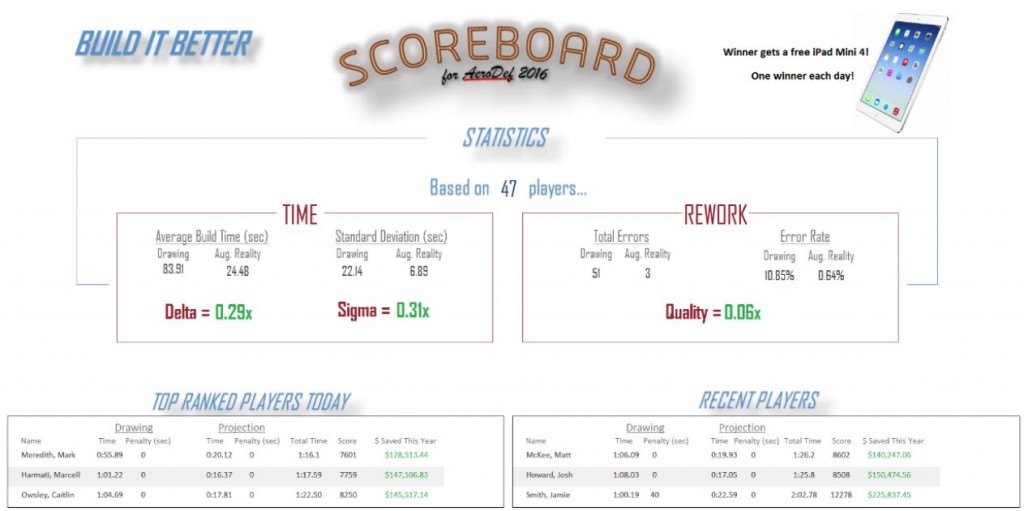

- Players were motivated. The motivating factor for participating (besides the competitive fun of it) was the chance for the fastest player each day to win an iPad 4. Each participant’s score was the total time for the two trials added together plus a 10-second penalty for each error (the “charge” for rework). Thus, each player was motivated to perform his or her best in both cases while being very careful not to make an error in either case.

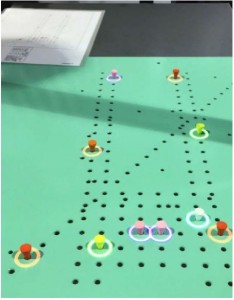

- Trials were randomized. There were 10 assembly variations; eight possible “part numbers,” of which only four were ever used in one assembly; and 153 possible insertion points for the parts with only 10 parts to install for each variant. Before starting, the participant would roll a pair of dice which would determine which method would be built first (traditional drawing or augmented reality), which variant would be built via traditional methods, and which variant would be built via augmented reality. In an informal exit poll of about 20% of the participants, there was unanimous agreement that the trials could not have biased the outcome in favor of augmented reality.

- The numbers we collected are for “value-added” work only. Even a system that can assure 100% efficiency produces no yield at all when the resource is not being applied to the assembly. All of the time spent by a person walking from the assembly to the parts bin, selecting the right parts, and walking back to the assembly accomplished putting exactly zero parts into the assembly — and, thus, added no value to the assembly during that entire time. The experiment was carefully crafted to minimize non-value-added work.

Execution of the experiment

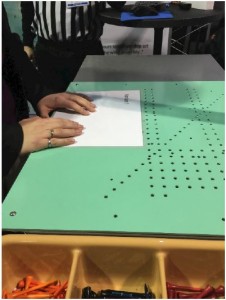

When a participant walked up and indicated that he or she wanted to play, the “referee” would go over the rules and the player would then roll dice to determine the setup of play. The stopwatch was started either at the start of projection or the turning over of the drawing. The stopwatch was stopped when the player called “done.”

Information was captured in an Access database from which the statistical data for the experiment was obtained. Access also ran the scoreboard, which generated a lot of interest in the experiment.

The dollar values shown are from a simple calculation using a $100-per-hour fully burdened rate and $100 per rework. The dollars saved is the annualized cost difference between the trials.

[cta]To answer more questions about optical projection and how it can make assembly operations better, faster, and cheaper, call DSC at (770) 575-5100 or email info@deltasigmacompany.com.[/cta]