How Much Does Augmented Reality Really Improve Human Performance?

As Delta Sigma Company talks to manufacturers about the benefits of the augmented reality products in our ProjectionWorks family, we hear one question repeatedly: “I can see that augmented reality is better than traditional methods to convey complex information — but how much better? I need a number.”

As Delta Sigma Company talks to manufacturers about the benefits of the augmented reality products in our ProjectionWorks family, we hear one question repeatedly: “I can see that augmented reality is better than traditional methods to convey complex information — but how much better? I need a number.”

The question is a natural one. Augmented reality is a complicated subject and applies in different ways to different types of tasks. To the uninitiated, the application of augmented reality seems daunting and risky.

For quite some time, we have struggled with how to answer this question truthfully without compromising any of our non-disclosure agreements. Delta Sigma Company has installed augmented reality systems on many aircraft production lines, and our clients universally send back glowing reviews such as these:

- “… saving 300 hours just on grip measurements alone …”

- “… time savings per shipset … 111 hours.”

- “During our first year of use, we had zero rework in the area where we use AssemblyWorks: a cost reduction of over $10 million compared to the prior year.”

- “Our bracket installation is now only 34% of the previous assembly method …”

- “… a cumulative, recurring, flyaway-cost savings of more than $82 million.”

- “Fastener installation was reduced by 150 hours on the mid-fuselage …”

- “… 96 hours saved per shipset for the wing assembly …”

- “AssemblyWorks reduced our nacelle assembly by 80 hours …”

- “… layout labor costs have been reduced by approximately 50%, and rework is down by 99%.”

- “On our very first use, a 14-hour task was done in four hours with zero errors.”

- “… we just completed our first panel using AssemblyWorks. It was the first one we ever made with no rework.”

Such testimonials are encouraging, but non-disclosure agreements prevent us from sharing the specifics of those applications with other potential clients.

Complex assemblies, but a simple proof

We recently realized that we had been thinking about it all wrong. Because augmented reality is commonly applied to rather complex assemblies, we had always envisioned that any fair comparison between augmented reality and traditional assembly methods would, of necessity, need to be complex.

Not so.

Upon deeper reflection, we realized tests only need to be very strictly controlled experiments in which

- an identical task is performed by a large number of people in two ways (with and without augmented reality); and

- we record accurate measurements of time and errors.

The use of augmented reality is the only difference between the two trials, so the difference in the measured values of time and errors represent the human performance enhancement caused by augmented reality.

Playing the game

To conduct our experiment, we created AssemblyWorks: The Game — a booth event that drew a wide variety of participants at the recent AeroDef Conference in Long Beach, California.

The premise of the game was simple: Each player performed a simple assembly task two times: once using instructions from an engineering drawing and once using an augmented reality projection. Eighty-five people participated, and each test was carefully randomized to eliminate potential advantages from observing other players and other factors.

The performance enhancements came from how the assembly instructions were transferred into the minds of the assemblers — the only difference between the two trials. As it turns out, how information is transferred makes a huge difference in how quickly and comprehensively it is understood by the receiver of that information.

The results were staggering

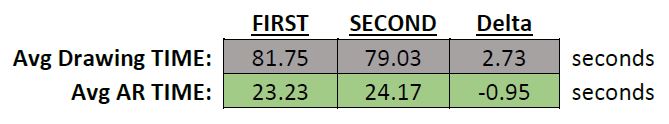

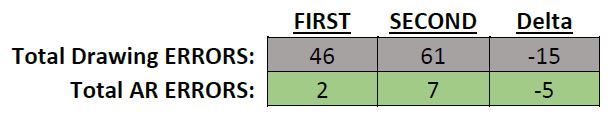

Using augmented reality to provide work instructions to assembly technicians causes an instantaneous human performance enhancement (HPE).

- Direct build-time speed increases by a factor of 3.5 times.

- Standard deviation is less than one-third of doing the same task using traditional methods.

- Errors are reduced by 92%.

For a wide array of assembly tasks, a high-quality augmented reality system can provide an instantaneous 70% reduction in the costs of value-added work with no risk to your assembly and no installation downtime on your production line.[/section]

Can your organization achieve these remarkable gains in productivity? Yes.

How you transfer the work instructions from the engineer to the technician really matters. The consequences are enormous. And the best part of all is that the workers are not working any harder than before to produce over three times more products. All of the gains are purely from improved efficiency.

[cta] Do the claims in this article seem too good to be true?

Do the claims in this article seem too good to be true?

We understand your skepticism!

To read the full account of our experiment at AeroDef and the report of the statistical data that forms the basis of these claims, download our white paper “The Effects of Augmented Reality on Human Performance.”[/cta]