In-Process Verification Makes Inroads

How costly are mistakes in wire harness assembly? For many organizations, such costs are difficult to quantify, as it depends on where in the process a mistake is discovered.

But why is rework simply accepted as part of the process? It’s time to change our mindset and our approach to verification and inspection.

In-process verification: A better idea

Typically, a final inspection catches any errors or mistakes in the manufacturing process. Materials are then reworked to correct such problems. However, this process is quite costly. Some mistakes can’t be fixed or have created additional problems by the time a product reaches inspection.

In contrast, in-process verification catches problems as quickly as possible, during assembly and manufacturing. Often, mistakes can be corrected immediately by the technician, at a much lower cost than during rework. In turn, errors no longer snowball.

Of course, this approach requires the proper tools, both to automate the verification process and to enable technicians to instantly see and correct errors.

See it, do it, check it, fix it

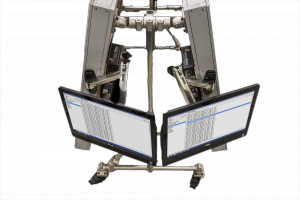

Verification needs can vary widely. In some instances, you simply need to confirm that an item has been placed; others might require confirmation of exact measurements. In either situation, tools such as AssemblyWorks and HarnessWorks, which create an optical projection directly on the work surface, can help to speed production and reduce, locate, and correct errors.

Both products project instructions onto the work surface, providing step-by-step instructions and guidelines for actions such as drilling and wiring. If an error is made — a drilled hole is slightly off-center, for example — discovery is nearly immediate, and the issue can be corrected while the assembly is still in-station. By the time the product reaches final inspection, the number of errors is greatly reduced, and any errors that are found tend to be much less severe — and less costly.

These types of in-process verification are perfect for:

- Hole and drilling placements and measurements

- Edge distance measurements, even on large-scale projects

- Skin surface measurements and positioning

- Wire harness and bracket placements

- Step and gap placements

In addition, optical projection and in-process verification enables greater standardization. Each assembly is laid out identically, so all pieces are produced to the same design and accuracy.

Are mistakes and rework completely avoidable? Perhaps not — but with the right tools, they can be reduced to negligible levels.

[cta]To answer more questions about how in-process verification can help you to reduce or avoid rework in your environment, call DSC at (770) 575-5100 or email info@deltasigmacompany.com.[/cta]